Blancpain: Story of the oldest watch

Watches manufactured in Le Brassus

Blancpain’s journey dedicated to the arts and crafts where engravers, master watchmakers, and enamellers devote their passion to the design and embellishment of high-value timepieces.

A custodian of watchmaking tradition, Blancpain nevertheless seeks to surprise with its spirit of innovation and taste for the provocative.

Founded in 1735 in the Swiss Jura by Jehan-Jacques, Blancpain is the world’s oldest watchmaking brand. Over the years it has invented countless complications, remaining ever-faithful to its tradition of innovation, and this quest for invention still drives the Master Watchmakers of the Manufacture today.

From the inception, the company focused on mechanical complications (Tourbillion, Perpetual Calendar, Minute Repeater, and Split Chrono). And, indisputably from then till now, Blancpain is always keenly accustomed to the watch connoisseurs. Its horological trade never fails to reflect the essence of the time.

Innovation is our Tradition

Throughout the course of its 282-year history, Blancpain has achieved an astounding array of successes, and can also be attributed for its unique masterpieces.

According to the archives the grand-nephew of the founder Jehan-Jacques, Frédéric Emile implanted the first Blancpain factory in 1815 in Villeret. He then modernized the production methods and transformed the traditional handicraft workshop into an industry capable of producing serial. By replacing the encounter wheel device with a cylinder exhaust, Frédéric-Louis introduced a major innovation in the world of watchmaking.

Manufacturing

Day after day, Blancpain perpetuates its historical links with Switzerland’s oldest watchmaking tradition by making its timepieces at Le Brassus and Le Sentier, respectively a village and a hamlet in the Joux Valley.

While the site in Le Sentier focuses more specifically on the manufacture of components and research and development, the Le Brassus operation concentrates on the arts and crafts and grand complications.

Blancpain is determined to push the boundaries of its inheritance through constant self-renewal and improve its timepieces by constantly challenging watchmaking constraints. At Blancpain, respect for their own watchmaking tradition is not felt as a barrier to innovation. On the contrary, the past history of the Manufacture of Le Brassus is an inexhaustible source of ideas.

Taking it as inspiration for pushing back frontiers is an on-going challenge at Blancpain.

Le Sentier

In the year 2010, Blancpain completed the vertical integration of its production by incorporating the sister company specialising in high-end movements, Frédéric Piguet SA. Ever since, the site in Le Sentier has regrouped the brand’s R&D teams, as well as a number of workshops. Several hundred staff members work there in creating, developing, testing, assembling and producing unique timepieces.

Le Brassus Manufacturing

Blancpain is born at the Brassus. It is natural that this hamlet of the Vallée de Joux has given its name to a collection that brings together the most learned models of the brand and reflects the know-how and innovation strength of the Manufacture.

The series of six masterpieces and especially 1735, witnesses Blancpain’s contribution to the revival of mechanical watchmaking, are his sources of inspiration. Masterpieces, great complications, discreet aesthetics and precious materials, the Le Brassus collection represents from the very beginning the values firmly anchored in our heritage.

In this spirit, the collection focuses today on the Carrousel, an exceptional mechanism rehabilitated and restored to the taste of the day by our Manufacture. By their aesthetic sober and effective, Le Brassus watches highlight the inner beauty of their complex and refined movements. Innovative technological advances and traditional design unite over the years to give shape to timepieces at the top of the watchmaking art.

Designing the masterpiece

Once the design concept is planned, the construction engineer creates drawings of the new watch using computer software. Using the drawings of watches as a basis, the specialized laboratory technicians assemble the prototypes.

Before being assembled, the decorating and engraving workshops takes care of the manufactured components.

Decoration of components

Master-craftsmen of the decoration workshop trained in-house, command a wide range of decorative techniques used in the trade for centuries:

Some of the techniques include flank drawing which is done on the flank, which is then rubbed lengthwise in order to form unidirectional longitudinal lines. Chamfering of the metal- by which sharp edges are faceted and polished.

For creating special designs on the watch and giving an illusion of spiral snailing is done; also circular graining is done on the plates and bridges with small circles applying a small overlapping circular pattern often on the non-visible sections such as the top and base plates.

Another beautiful yet adorning watch finishing includes Geneva stripes also known as Geneva waves. It’s a decoration resembling waves formed by grinding on bridges and oscillating weights.

Mirror polishing is a technique by which a block of zinc is polished with an abrasive paste called “diamantine” until it is as perfectly smooth and shiny as a mirror.

The manually performed work of these craftsmen achieves a result that no machine could ever attain, such as the perfect clarity of a chamfer. It also offers the craftsman freedom of expression. During circular graining, it is he who decides on the position of each circle. To cite one example, it takes a whole month of work to decorate the 70 components of the Minute Repeater calibre 332.

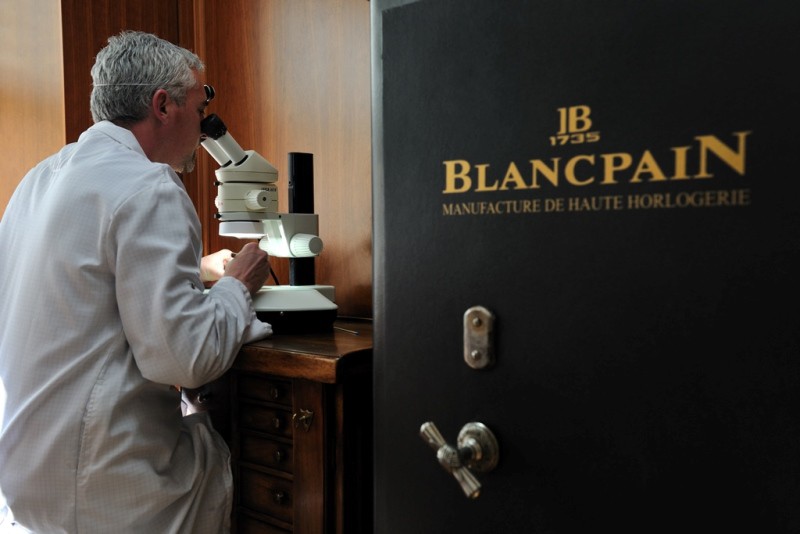

Engraving

Watch aficionado has always paid particular attention to the decoration of art objects, pocket watches or wristwatches. Blancpain continues that tradition and has dedicated a workshop to this ornamental technique. Using a small graving tool and a microscope the engravers reproduce sketches drawn by hand by making incisions in the material.

On some case-backs or oscillating weights, four engraving artists create worlds peopled with creatures, divine or mischievous. The engraving is executed entirely by hand using a small graver, without the aid of any digital technique.

One of our master-engravers adorns certain timepieces with automaton scenes. Of course, it is possible to personalise a watch by having it engraved with a motif of your choice.

Assembly

Last but not least, the complications workshop brings together the master watchmaker to assemble the A to Z of the watch. Every Blancpain watch is assembled entirely by hand in our workshops by a single watchmaker, respecting the tradition of the watchmaker’s craft. The assembly of a watch is a process in which every move has to be perfect: not the slightest shortcoming can be tolerated at any stage.

The watchmakers start by assembling and regulating the movement, before equipping it with a dial, hands, a case and a strap or bracelet.

Among the great successes of the manufacture is the Fifty Fathoms, launched in 1953 and produced at the request of French Combat Swimmers who need a reliable watch for their underwater expeditions.

Numerous other creations include the Unique Artistic Crafts Piece of Ganesh Watch and Villeret, Running Equation of time giving a great essence of craftsmanship and style.

More from our site

Recent Posts

Where to Sip the Best Whisky Cocktails in India

On International Whisky day, head to these restaurants to sip the finest whisky cocktails

On International Whisky day, head to these restaurants to sip the finest whisky cocktails

The New Defender OCTA: Epitome of Power, Luxury and Performance

New Defender OCTA is the most dynamically accomplished Defender ever created, with unmatched breadth of capability and performance both on- and off-road

New Defender OCTA is the most dynamically accomplished Defender ever created, with unmatched breadth of…

Shaping Tomorrow’s Golf Champions With Leela Palace Bengaluru

The 3rd edition of The Leela Golf Tournament celebrated young talent and brought together skill, precision and camaraderie!

The 3rd edition of The Leela Golf Tournament celebrated young talent and brought together skill,…

The Duo Behind Late Checkout, Redefines Hospitality

In conversation with the founders of Pawan Shahri and Nikita Harisinghani, the duo behind Chrome Hospitality Asia

In conversation with the founders of Pawan Shahri and Nikita Harisinghani, the duo behind Chrome…

Precision, Durability, and Swiss Legacy

Victorinox launches the Swiss Army collection, featuring three distinct models that emphasise exceptional quality, resistance and versatility

Victorinox launches the Swiss Army collection, featuring three distinct models that emphasise exceptional quality, resistance…

A New Era of Luxury Interiors With Sussanne & Gauri Khan

Sussanne Khan & Gauri Khan unite to bring an awe-inspiring, six-storey sanctuary of luxury, art, and design in Hyderabad

Sussanne Khan & Gauri Khan unite to bring an awe-inspiring, six-storey sanctuary of luxury, art,…